Site I.4

Site ID

I.4

Health

COD

2015

Nominal Capacity

60 kWp

Average Specific Yield

1180 kWh/kWp

Total Estimated Loss

9%

Possible Gain

5% to 7%

CAPEX, OPEX

4.4 ₹/Wp, 0.4 ₹/Wp/a

Expenditure / Energy

N/A

Abstract

The PV plant shows high levels of soiling caused by pollution, bird droppings and hard water, and significant module damages caused by bad handling. The modules are also affected by product defects. The mounting structure is in very bad shape and will likely not last for the whole project lifetime. It is recommended to (i) increase the cleaning frequency to at least 3 times per month (ii) replace the modules exceeding the manufacturer’s guaranteed performance drop and (iii) reinforce immediately the structural integrity of the mounting structure. The estimated production boost caused by the retrofitting actions lies between 5% and 7%.

Main Findings

Heavy soiling has been detected on site. The use of hard water for cleaning increases the accumulation if soil on the module surface. This leads to soiling induced hotspots.

The mounting structure is heavily rusted and likely not to last until the end of the project’s lifetime. Besides, the structure is not robust for the height and number of the installed modules.

Loose connectors were found in many PV modules

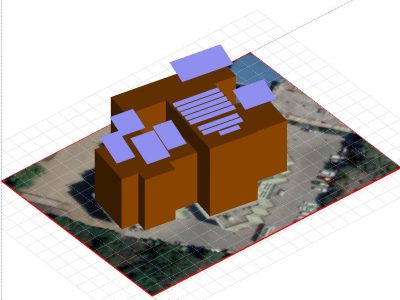

Near shadings are caused by the fence, water tank and surrounding structures.

A significant amount of PV modules show inactive cells strings, scratches and cuts at the backside, junction boxes without lid and browning of the EVA.

Impact on Performance

Near Shading

The irradiance losses caused by near shading is quantified as ca. 3%.

Estimated Loss

≈ 3%

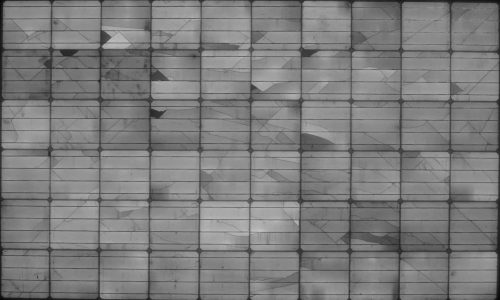

Cell Cracks

Based on the crack distribution and types detected with electroluminescense, is it likely that the modules perform 2-4% less. Furthermore, these types of crack could eventually lead to inactive areas and higher power losses in the midterm.

Estimated Loss

2%-4%

≈ 3%

Inactive Cell Strings

Modules with inactive cell strings underperform 33% to 66% depending on the amount of affected strings. The extrapolation of the inspected sample to the whole system leads to a loss of 3% at system level.

Estimated Loss

≈ 3%

Total Estimated Energy Loss

≈ 9%

Proposed Solutions

The mounting structure should be retrofitted immediately.

Defective and loose connectors should be replaced and the connectors should be homogenized.

The irradiation sensor should be properly installed in order to ensure accurate performance ratio calculations.

All modules with inactive cell strings shall be replaced according to the warranty terms. A similar exercise shall be conducted with all modules showing product defects.