Site 2.58

Site ID

2.58

Health

COD

2018

Nominal Capacity

670 kWp

Average Specific Yield

747 kWh/kWp

Total Estimated Loss

23.9%

Possible Gain

12% to 17%

CAPEX, OPEX

0.5 ₹/Wp, 0.15 ₹/Wp/a

Expenditure / Energy

1.6 ₹/kWh to 1.1 ₹/kWh

Abstract

The PV plant is heavily soiled. Some modules with mechanical damages were detected (broken modules and damaged frames). Cables hang under the modules and damaged cable conduits and MC4 connector were found. Interrow distance is insufficient. Structural earthing is incomplete and corroded. It is recommended to (i) increase the cleaning cycles, (ii) replace damaged modules and cables, (iii) retrofit the mounting structure, (iv) install a new earthing system, and (v) install a weather station or at least an irradiation sensor on the module plane to quantify and monitor the Performance Ratio. The estimated production boost expected by the retrofitting actions lies between 12% and 17%.

Main Findings

Poor cable management: Broken, burnt, and open cable conduits, cables hanging loose, and no string labelling.

Six broken modules were found on site and other five showed a damaged frame.

A plant section was uninstalled due to a new construction, reducing its nominal capacity.

Broken, open, burnt, and weather exposed MC4 connectors are found on site.

No LA was found close to the system.

No weather station, and hence no PR monitoring.

An inverter shows heavy degrees of soiling in the fan and the labelling of some others are degraded.

Few tables have structural earthing and those with it present rusted contacts.

Walkways for maintenance are missing and the ones existing are rusty.

Several objects were found casting shadows over the modules, such as, small trees, a cable conduit, and a plastic sheet.

Impact on Performance

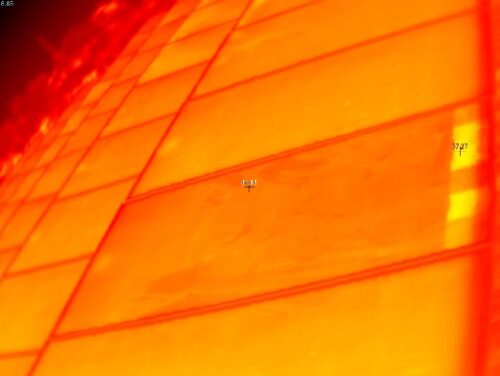

Heavy Soiling

The system presents heavy degrees of soiling. The on-site measured soiling losses were estimated in 13.1%.

Estimated Loss

≈ 13.1%

Self Shading

IR analysis showed that interrow shading developed hot cells in the bottom part of the modules. According to the PVsyst simulation, self-shading losses account for up to 6.3%.

Estimated Loss

≈ 6.3%

Cell Cracks

According to the number of cracks discovered via EL imaging; the system is not expected to have large power losses due to inactive areas.

Estimated Loss

≈ 4%

Total Estimated Energy Loss

≈ 23.9%

Proposed Solutions

The cleaning cycles of modules and inverters shall be increased based on the results of a soiling study that adjusts the cleaning needs to each season.

All broken and damaged modules shall be replaced.

The cables shall be fixed to the mounting structure and the cable conduit renovated with UV protection.

A weather station, or at least an irradiation sensor on the module plane, shall be installed so that the performance of the system can be properly determined.

Foreign objects casting shadows over the modules shall be removed.

The whole site should have safe walkways installed to carry out O&M tasks.

Earthing of the complete mounting structure shall be renovated and bonding between modules included.

LA shall be relocated closer to the PV system.

Include in the O&M practices the cleaning of the ventilation system of the inverters.

If possible, the interrow distance and tilt angle should be improved to reduce self-shading.