Site 2.50

Site ID

2.50

Health

COD

2017

Nominal Capacity

150 kWp

Average Specific Yield

1081 kWh/kWp

Total Estimated Loss

24.4%

Possible Gain

8% to 12%

CAPEX, OPEX

0.63 ₹/Wp, 0.12 ₹/Wp/a

Expenditure / Energy

1.8 ₹/kWh to 1.1 ₹/kWh

Abstract

The PV plant consists of a 50.24 kWp and a 100.48 kWp system. Structural earthing is corroded and bonding between modules is absent. The system design disregarded near shading. Poor cable was management was found. The plant is modestly affected by soiling and bird droppings. It is recommended to (i) improve O&M activities, (ii) retrofit earthing system and cabling management, (iii) replace a damaged connector, and (iv) re-arrange the strings based on the shading. The estimated production boost expected by the retrofitting actions lies between 8 and 12%.

Main Findings

Filters of the inverters were found soiled.

The pyranometers found on site were not properly aligned to the plane of the array.

A broken connector was found on-site.

Bird droppings and traces of paint were

found on some modules

Poor management of grounding: No earthing connection was found between modules and some elements are rusted.

Impact on Performance

Self Shading

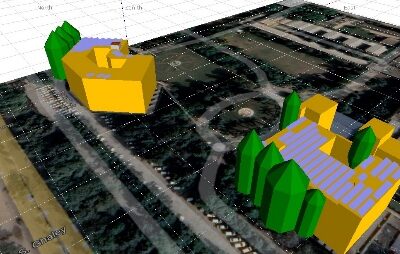

According to the simulation of the system, the self-shading losses of both subsystems account for up to 7.9%.

Estimated Loss

≈ 7.9%

Inhomogeneous tilt angle

The deviation of optimal angle (14°) losses of both subsystems account for up to 3.6%.

Estimated Loss

≈ 3.6%

Near Shading

Objects near the system, such as, buildings and trees, cast shadows over the system, accounting for losses around 7.8%

Estimated Loss

≈ 7.8%

Cell Cracks

Based on the number of cracks and isolated parts discovered during Electroluminescence analysis, the power loss is expected to be around 2%.

Estimated Loss

≈ 2%

Underperformance

The underperformance of the measured modules is around 3.1%.

Estimated Loss

≈ 3.1%

Total Estimated Energy Loss

≈ 24.4%

Proposed Solutions

The irradiance sensor shall be installed on the module plane so that the performance of the system can be properly determined.

Broken MC4 connector should be replaced.

The trees surrounding the system shall be trimmed if allowed. Additionally, restringing of the modules in the shaded areas shall be conducted in the following way: modules with similar shading conditions shall be installed in the same string or MPPT.

Include in the O&M practices the cleaning of the ventilation system of the inverters.

If there is sufficient space, modules tilt shall be changed to optimal tilt of 30°.

Earthing connections between modules shall be added and rusted elements substituted.

The cleaning cycles shall be increased based on the results of a soiling study that adjusts the cleaning needs to each season.

All cables should have a suitable labelling and the UV protection against the weather renewed.