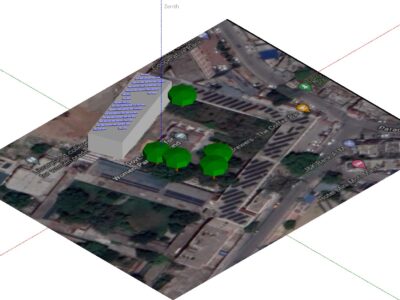

Site 2.4

Site ID

2.4

Health

COD

2018

Nominal Capacity

50 kWp

Average Specific Yield

168 kWh/kWp

Total Estimated Loss

46.2%

Possible Gain

5% to 15%

CAPEX, OPEX

1.3 ₹/Wp, 0.14 ₹/Wp/a

Expenditure / Energy

23.0 ₹/kWh to 7.9 ₹/kWh

Abstract

The PV plant shows design failures such as self-shading, near shading, and the inadequate tilt angle. Vegetation has grown around and under the modules, which has caused hot cells on the system. No earthing between modules was found, the structure had no insulation coating, an inverter works under “UNGV” alarm, and leak current was present. It is recommended to: (i) increase the cleaning frequency, (ii) install an irradiation sensor on the tilted plane to estimate and check the Performance Ratio, (iii) ensure the operator’s security, and (iv) a new method to fix the modules shall be used. The estimated production boost expected by the retrofitting actions lies between 5% and 15%.

Main Findings

No earthing connection between modules.

No insulation coating on structure could represent a risk for maintenance workers and engineers while performing O&M works in case of current leakage.

Existence of current on system after the inverter was turned off.

Inverter is always under alarm “UNGV”.

Access to sites is complicated.

Modules are not properly fixed to the ground and the wires used to fix them to the structure were damaged and rusted.

The tilt angle (10°) causes lost around 5.4% due to its deviation from optimal.

Plants have grown under and around the modules due to no maintenance works since the commissioning of the site.

Impact on Performance

Near Shading

The ballasts used as deadweights to hold the low heighted system and vegetation around it cast shadows on the modules resulting in hotspots.

Estimated Loss

≈ 0.2%

Heavy Soiling

Soiling losses around 3% were measured on site.

Estimated Loss

≈ 3%

Cell Cracks

Giving to the EL imaging, the system is not expected to have a large power loss.

Estimated Loss

≈ 3%

Underperformance

The underperformance of the measured modules is around 31%.

Estimated Loss

≈ 31%

Total Estimated Energy Loss

≈ 46.2%

Proposed Solutions

The cleaning cycles and a maintenance program shall be stablished based on the results of a soiling study that adjusts the cleaning needs to each season and vegetation growth.

A weather station, or at least an irradiation sensor on the module plane, shall be installed so that the performance of the system can be properly determined.

New methods shall be used to fix the modules to the structure.

Earthing connections between modules shall be added.

The operator’s safety must be secured by isolating the structure and identifying and replacing of malfunctioning components in case of current leakage.