Site 2.3

Site ID

2.3

Health

COD

2018

Nominal Capacity

50 kWp

Average Specific Yield

970 kWh/kWp

Total Estimated Loss

37.17%

Possible Gain

5% to 12%

CAPEX, OPEX

2.4 ₹/Wp, 0.12 ₹/Wp/a

Expenditure / Energy

4.8 ₹/kWh to 2 ₹/kWh

Abstract

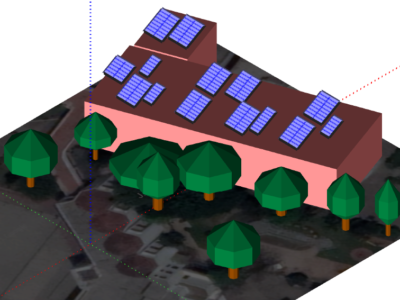

The PV plant has several broken modules. Some modules are installed in the risk wind zone. There is no lightning arrestor for on the roof. The building services vent directly under the modules. It is recommended to (i) replace to broken modules and rusty clamps, (ii) install a lightning arrestor (iii) continuous cleaning of the modules especially the bird drops (iv) restringing of shaded modules, and (v) yearly thermography inspection of the modules. The estimated production boost expected by the retrofitting actions lies between 5 and 12%.

Main Findings

There is no weather station, and hence no PR monitoring.

Damaged modules are connected to the system, resulting in low generation.

Exhaust ventilation system under module: the ambient temperature under or around the modules shall be kept as low as possible. An exhaust vent under modules will harm the module’s life.

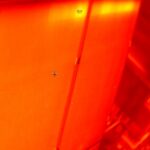

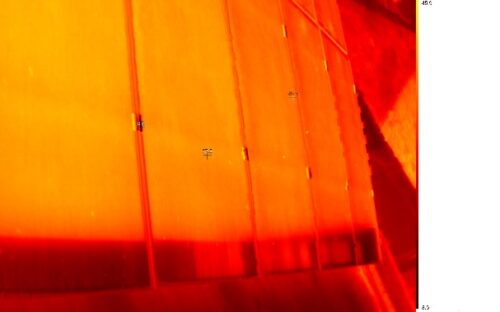

Damaged modules due to mechanical impact, resulting in burned module.

Rusted clamps and structures are found all over the site.

No LA found on the roof.

Modules were installed to close to the roof edge, having a distance not suitable for maintenance activities of 250mm. In addition, the wind loads are increased due to this reason.

All module nameplates are washed away and model and producer cannot be read.

Impact on Performance

Heavy Soiling

Low generation due to heavy soiling and bird droppings. Modules are cleaned once a month. Shadings due to soiling produces losses in the system performance. The measured soiling loses is 2%

Estimated Loss

≈ 2%

Near Shading

Major Shading from nearby obstructions: Hotspots can be created due to shading from modules ahead of it.

Estimated Loss

≈ 1.4%

Underperformance

The underperformance of the measured

modules is around 25.4%

Estimated Loss

≈ 25.4%

Total Estimated Energy Loss

≈ 37.17%

Proposed Solutions

The cleaning cycles shall be increased based on the results of a soiling study that adjusts the cleaning needs to each season.

Burned modules should not be connected to the system to avoid further damages. It should be replaced or removed.

The exhaust ventilation system should be redirected to the opposite direction, to avoid higher temperature under the modules.

Rusted clamps and structure should be replaced if possible. To prevent such problems, metal objects vulnerable to corrosion can be painted with zinc.

It is recommendable to have lightning arrestor on the roof.

A weather station, or at least an irradiation sensor on the module plane, shall be installed so that the performance of the system can be properly determined.

A re-stringing of the modules from the shaded areas shall be conducted in the following way: modules with similar shading conditions shall be installed in the same string or at least assigned to individual MPPTs.