Site 2.28

Site ID

2.28

Health

COD

2017

Nominal Capacity

80 kWp

Average Specific Yield

909 kWh/kWp

Total Estimated Loss

30.86%

Possible Gain

20% to 25%

CAPEX, OPEX

1.5 ₹/Wp, 0.5 ₹/Wp/a

Expenditure / Energy

2.2 ₹/kWh to 1.8 ₹/kWh

Abstract

Several modules with open j-boxes and corroded contacts were found, posing severe threat to people. Loosely hanging cables with low bending radius were found. Modules are significantly soiled. It is recommended to (i) replace modules with corroded contacts, (ii) increase the cleaning cycles, (iii) reestablish the earthing connection between structures, (iv) retrofit the mounting structure, and (v) install a weather station or at least an irradiation sensor on the module plane. The estimated production boost expected by the retrofitting actions lies between 20% and 25%.

Main Findings

Poor cable management: Cable layout with low bending radius. In addition, table and string labelling are missing.

The conduit housing the cables are broken, exposing the cables and connectors to ambient conditions without any UV protection.

Inverters filters and fans are soiled and are noisy in operation.

Bolts used in mounting structures showed signs of rusting.

The modules are heavily soiled.

Earthing between tables is disconnected.

Modules are misaligned due to improper

bolt fixation.

Modules with open J-boxes and corroded contacts were found, posing a severe risk to people and equipment.

No weather station identified on site.

Modules with different year of manufacture were used in same string.

Impact on Performance

Heavy Soiling

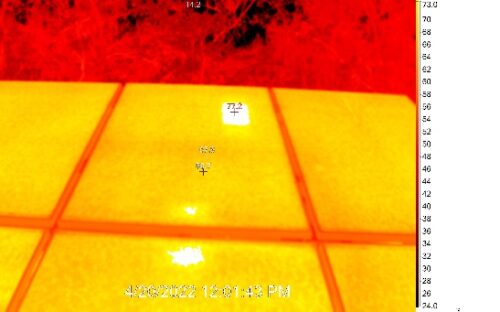

The system performance was affected significantly by soiling loss of 20%, estimated from IV curve measurements. IR analysis shows presence of hotspots from soiling.

Estimated Loss

≈ 20%

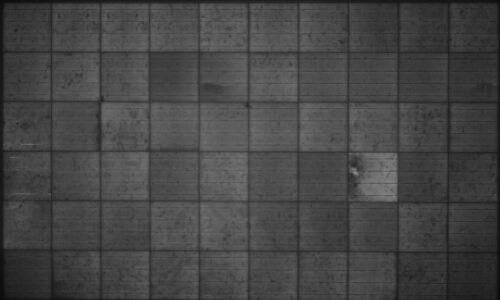

Cell Cracks

The EL image reveals presence of long cracks, which arises due to issues in transportation or handling. These cracks are not expected to impact performance in their given state.

Estimated Loss

≈ 4%

Underperformance

Based on the IV curve measurements, the estimated underperformance is 4% for the measured modules.

Estimated Loss

≈ 4%

Total Estimated Energy Loss

≈ 30.86%

Proposed Solutions

The cleaning cycles shall be increased based on the results of a soiling study that adjusts the cleaning needs to each season.

Strings, tables, and inverters should have a suitable labelling (UV-resistant).

The cable layout can be optimized; the minimum cable bending radius is 10x the cable diameter.

Modules with open J-boxes and corroded contacts shall be replaced.

A re-sorting of modules shall be conducted to have modules with same year of manufacture in the same string or at least same MPPT.

A re-stringing of modules shall be conducted to have shaded modules in the same string or at least same MPPT.

A weather station, or at least an irradiation sensor on the module plane shall be installed.

Earthing strips between structures shall be properly connected.

Bolts and nuts shall be properly fixed to reduce module misalignment and improve safety. Polymer end clamps shall be replaced since they are unsuitable.

Rusted joints should be replaced if possible. To prevent such problems, metal objects vulnerable to corrosion can be painted with zinc.