Site 2.25

Site ID

2.25

Health

COD

2018

Nominal Capacity

27.5 kWp

Average Specific Yield

1374 kWh/kWp

Total Estimated Loss

22.18%

Possible Gain

5% to 7%

CAPEX, OPEX

3.1 ₹/Wp, 0₹/Wp/a

Expenditure / Energy

2.1 ₹/kWh and 1.5 ₹/kWh

Abstract

Cable layout with loosely hanging cables were found. Modules with manufacturing and other defects were found on site. Several structure related problems were observed. It is recommended to (i) optimize cable layout, (ii) replace defective modules, (iii) re-sort and restring modules, (iv) replace faulty and unsuitable clamps and structures, and (v) install a weather station. The estimated production boost expected by the retrofitting actions lies between 5% and 7%.

Main Findings

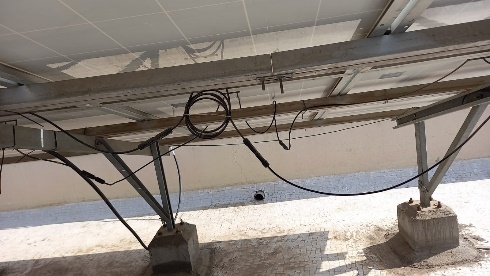

Poor cable management: The cables were observed to be loosely hanging, without string labelling, and exposed to ambient.

Many modules were dislodged and lost due to a cyclone incident. Replacement modules of different power rating and dimensions were mounted onto the same structure.

Inverter fans and filters are soiled.

Module defects such as broken back- sheet, sealant on cell, moisture ingress, and sealant gap around junction box found.

The connections between structure purlins in a table was established by varying screws per plate.

Clamps of different types were used in the same table, also causing an imbalance in the load on the modules.

IR analysis indicates hotspots and hot cells on modules due to sealant on cell and broken cells.

Impact on Performance

Heavy Soiling

Soiling loss of 1% were estimated from IV curve measurements.

Estimated Loss

≈ 1%

Cell Cracks

The EL image reveals several isolated parts, which may have caused from handling issues, the cyclone incident, or imbalanced loading.

Estimated Loss

≈ 4%

Underperformance

Based on the IV curve measurements, the estimated underperformance is 12.3% for the measured modules.

Estimated Loss

≈ 12.3%

Near Shading

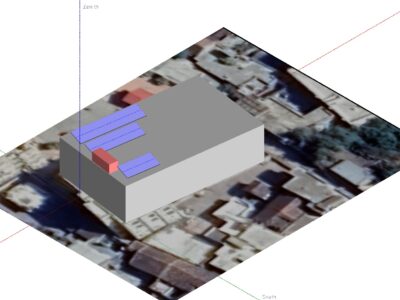

According to the PVsyst simulations, the near shading losses account to 1.31%, and 1.5% tilt loss relative to optimal tilt.

Estimated Loss

≈ 1.31%

Total Estimated Energy Loss

≈ 22.18%

Proposed Solutions

Loosely hanging cables shall be routed using appropriate tags. UV protection measurements shall be taken by a suitable rack with roof or cable coating.

The inverter filters and fans shall be cleaned.

Manufacturing defects shall be investigated for possible warranty claim.

Modules with broken back-sheet and sealant gap pose performance and safety threats, which shall be replaced.

A re-sorting of modules shall be conducted so that the lower performing modules are in the same string or at least in the same MPPT.

A re-stringing of modules shall be conducted so that the shaded modules are in the same string or at least same MPPT.

Module tilt shall be changed to optimal tilt of 25°.

Clamp variations used in the same table shall be replaced with appropriate clamps of same type. The structure and components shall be replaced or retrofitted to sustain any future damages from cyclones.

A weather station, or at least an irradiation sensor on the module plane shall be installed.