Site 2.22

Site ID

2.22

Health

COD

2018

Nominal Capacity

39.7 kWp

Average Specific Yield

1033,7 kWh/kWp

Total Estimated Loss

28.42%

Possible Gain

17% to 20%

CAPEX, OPEX

2.54 ₹/Wp, 0.33 ₹/Wp/a

Expenditure / Energy

2.5 ₹/kWh to 2.2 ₹/kWh

Abstract

Some shaded and heavily soiled modules were found. A module with glass breakage was found to be connected to the system. It is recommended to (i) replace broken parts of the cabling and connectors, (ii) replace the rusted screws, (iii) change the module tilt to the optimal value, (iv) re-string the shaded or broken modules, (v) increase the cleaning cycle, and (vi) install a weather station or at least an irradiation sensor. The estimated production boost expected by the retrofitting actions lies between 17% and 20%.

Main Findings

Some modules have slipped due to improper mounting.

The screws used in the mounting structures showed signs of rusting.

Some parts of the modules were installed underneath roofs and have significant shading.

A module with a broken glass is still connected.

No weather station identified on site.

Access to the second part of the roof is difficult, which makes module cleaning and maintenance difficult.

Shoe-prints were found on some modules.

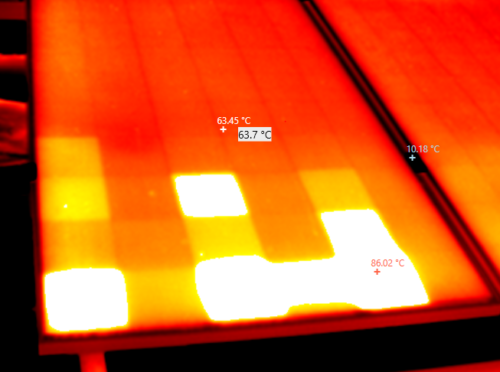

The Thermographic examination indicates irreversible cell damage due to shading.

Impact on Performance

Heavy Soiling

The system performance was affected by soiling losses of 10.9%, estimated from IV curve measurements.

Estimated Loss

≈ 10.9%

Cell Cracks

The EL image reveals presence of micro- cracks and isolated parts, which are representative of poor handling during installation or maintenance.

Estimated Loss

≈ 2%

Underperformance

Based on the IV curve measurements, the estimated underperformance is 8.5% from the measured modules.

Estimated Loss

≈ 8.5%

Inhomogeneous tilt angle

According to PVsyst simulations, The module tilt deviates about 5° from the optimal position, which leads to about 1.6% losses.

Estimated Loss

≈ 1.6%

Total Estimated Energy Loss

≈ 28.42%

Proposed Solutions

If there is sufficient space on the roof, the module tilt shall be adjusted.

A re-sorting of modules shall be conducted to have lower performing modules in the same string or at least same MPPT.

A re-stringing of modules shall be conducted to have shaded modules in the same string or at least same MPPT.

Damaged or burnt connectors must be replaced.

The cleaning cycles shall be increased based on the results of a soiling study that adjusts the cleaning needs to each season.

A proper O&M plan including training shall be established. This helps in improved performance and safety of the plant.

A weather station, or at least an irradiation sensor on the module plane shall be installed so that the performance of the system can be properly determined.

Modules with broken glass shall be replaced since they pose a safety risk and impact the performance.

Rusted screws should be replaced if possible.