Site 2.19

Site ID

2.19

Health

COD

2017

Nominal Capacity

20 kWp

Average Specific Yield

1144 kWh/kWp

Total Estimated Loss

43.82%

Possible Gain

10% to 15%

CAPEX, OPEX

2.91 ₹/Wp, 2.14 ₹/Wp/a

Expenditure / Energy

12.6 ₹/kWh to 8.4 ₹/kWh

Abstract

Some modules with mechanical damages were detected (micro-cracks and burned cells). Cables hang under the modules. Interrow distance is insufficient. Structural earthing is incomplete and corroded. It is recommended to (i) increase the cleaning cycles, (ii) replace damaged modules and cables, (iii) retrofit the mounting structure, (iv) install a new earthing system, and (v) install a weather station or at least an irradiation sensor on the module plane to quantify and monitor the Performance Ratio, (vi) remove objects under modules. The estimated production boost expected by the retrofitting actions lies between 10 and 15%.

Main Findings

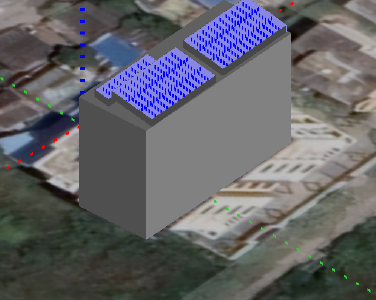

Modules have been installed over the edge limits of the building, increasing the wind load on the panels. Not possible to reach the panels for cleaning.

Mounting structure is mostly rusted on welded areas and fasteners.

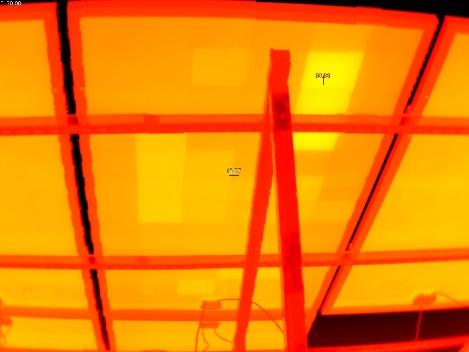

Modules with burned cells

Connectors are mostly soiled.

J-boxes with burned contact were found.

Bad cable management.

No LA found on site.

No weather station was found.

Conduits rest in the mounting structure and the panel that may be cause micro cracks.

The bonding between modules is absent.

Different junction box found that indicates there is a different solar panel model.

Modules with manufacturing defect; the system is not expected to have large power losses due to this issue

Impact on Performance

Heavy Soiling

The on-site measured soiling losses were estimated in 11%.

Estimated Loss

≈ 11%

Underperformance

The underperformance of the measured modules is around 23,04%.

Estimated Loss

≈ 23.04%

Total Estimated Energy Loss

≈ 43.82%

Proposed Solutions

A weather station, or at least an irradiation sensor on the module plane, shall be installed so that the performance of the system can be properly determined.

The site should have walkways installed in order to carry O&M activities safely.

Modules with defective manufacturing problems, modules with burned back- sheet, and modules with moisture should be replaced.

Earthing connections between modules shall be added.

Based on the soiling calculated, the cleaning cycles shall be increased to a weekly base.

In case it is possible, modules that are installed beyond the edge area of the building should be moved in order to reduce the wind loads.

Rusted clamps and structure should be replaced if possible. To prevent such problems, metal objects vulnerable to corrosion can be painted with zinc.

The cable layout can be optimized.

It is recommendable to have lightning

arrestor on the roof.