Site IV.9

Site ID

IV.9

Health

COD

2015

Nominal Capacity

100 kWp

Average Specific Yield

1065 kWh/kWp

Total Estimated Loss

15.3%

Possible Gain

8% to 14%

CAPEX, OPEX

1.3 ₹/Wp, 0.2 ₹/Wp/a

Expenditure / Energy

N/A

Abstract

The plant is affected by significant city pollution, minor near shadings and bird drops. Additionally, isolation and safety issues cannot be excluded due to damaged cables by sharp edges. Electroluminescence imaging exposed different module mechanical damages, likely induced during handling and installation. It is recommended to (i) conduct a string reengineering with individual MPPT assignment, based on IR inspection, (ii) improve O&M activities (particularly cleaning) and, (iii) retrofitting of DC cable (sharp edges, bending radius). The estimated production boost expected by the retrofitting actions lies between 8-14%.

Main Findings

The system displays poor cable management, e.g., loose connectors, cables in contact with sharp edges and loose DC cables behind the modules.

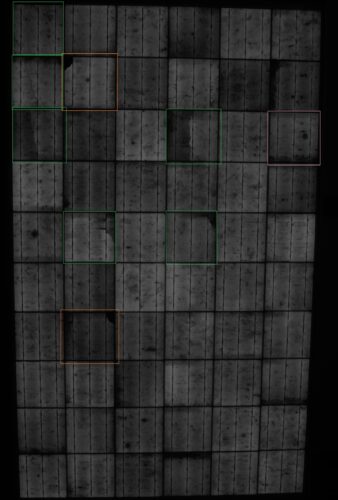

Electroluminescence imaging revealed an important variety of cell cracks.

Module defects, such as snail trails, label detachment, corrosion in the busbars, and modules with tight bending radius were discovered.

The inverter fan filters (outlets) are partially blocked, leading to a higher risk of inverter shut down.

The calibration date of the irradiation sensor was not provided.

Impact on Performance

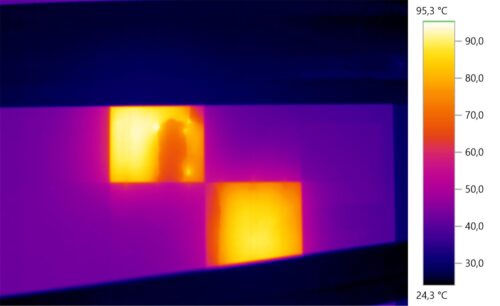

Heavy Soiling

Soiling measurements were conducted measuring nominal power before and after cleaning at irradiations higher than 900 W/m2. The estimated soiling factor is in the range of 5-6%.

Estimated Loss

5%-6%

≈ 5.5%

Near Shading

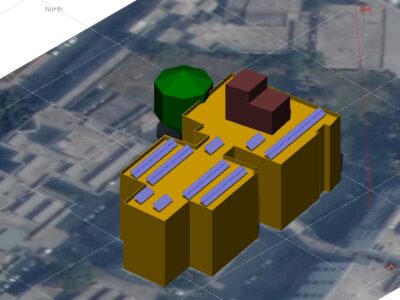

The losses due to near shadings could represent 2.3% less irradiance loss, based on a representative simulation.

Estimated Loss

≈ 2.3%

Cell Cracks

Due to the limited access to the rooftop (staircases) it is likely that the modules suffered increased mechanical loads during transportation, handling and installation. The amount and type of cracks discovered via EL, as well as the snail trail distribution, could be an indicator of a performance drop between 5-10%.

Estimated Loss

5%-10%

≈ 7.5%

Total Estimated Energy Loss

≈ 15.3%

Proposed Solutions

Modules with a large amount of cracks (including snail trails), shall be regrouped in the same string or at least assigned to one MPPT. The grouping shall be conducted based on infrared inspection with high irradiation levels and after cleaning activities.

The manual cleaning cycles shall be implemented and scheduled based on the results of a soiling study that adjusts the cleaning needs to each season.

The lack of calibration of the irradiation sensor will not directly affect the performance of the system. However, the accurate recording of the onsite irradiation will provide confidence to the plant`s KPIs.

Damaged cables (sharp edges) shall be replaced. Furthermore, the minimum bending radius shall always be respected.

Snail trails shall be monitored to validate whether they have stabilized over time.