Site IV.8

Site ID

IV.8

Health

COD

2015

Nominal Capacity

80 kWp

Average Specific Yield

1048 kWh/kWp

Total Estimated Loss

6.7%

Possible Gain

5% to 14%

CAPEX, OPEX

0.8 ₹/Wp, 0.2 ₹/Wp/a

Expenditure / Energy

N/A

Abstract

The system's DC cabling is in poor condition and should be fixed. The monitoring system shows incorrect values and the system is partially shaded by trees and cables. Furthermore, the modules showed substantial underperformance and some are affected by shunts. It is recommended to (i) repair the monitoring system, (ii) improve plant cleaning, (iii) replace modules exceeding the manufacturer’s guaranteed performance drop and (iv) replace modules with defects shunts or broken diodes. The estimated production boost caused by the retrofitting actions lies between 5-14%.

Main Findings

String cables damaged by or in contact with sharp edges were spotted.

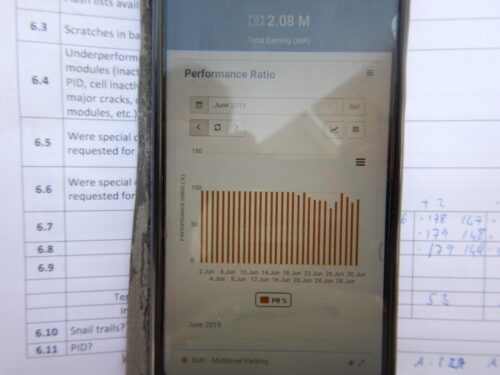

The monitoring of the system shows PR values of 100%. This indicates incorrect input values from the sensors.

The radiation sensor cables are not installed correctly.

Some parts of the cables are exposed to UV radiation. Pipes conveying cables are open and some parts have already broken.

The grounding of the system is interrupted in some places and is therefore not guaranteed.

The inlets and outlets of the ventilation system of the inverters are dirty.

Cable ties broke, hence the module cables and connectors are loosely hanging.

Some modules have oxidized bus bars.

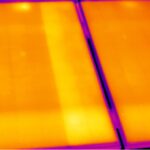

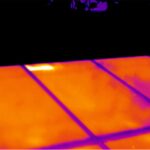

Several modules with shunt damage were found during the visual inspection.

Some modules have local contamination that leads to hotspots.

A module with an active diode was found.

Impact on Performance

Heavy Soiling

Based on the measurements on-site, soiling losses were determined to be 5.2%, on average.

Estimated Loss

≈ 5.2%

Near Shading

Some parts of the plant are permanently shaded by trees or cables. The simulation of the system showed a shading loss of 1.5%.

Estimated Loss

≈ 1.5%

Total Estimated Energy Loss

≈ 6.7%

Proposed Solutions

The entire DC wiring should be checked for safety.

Broken modules that do not meet the warranty requirements should be replaced.

Local shading caused by trees or cables should be removed.

The frequency of cleaning should be increased and significant dirt should be removed.

PV modules showing power drops above the warranty conditions should be replaced. If the replacement is not possible, the modules should be regrouped in power classes within the same string and assigned to individual MPPTs.

The radiation sensors should be calibrated.