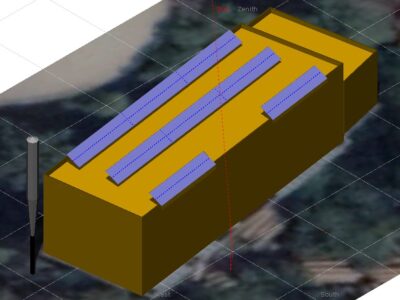

Site IV.6

Site ID

IV.6

Health

COD

2015

Nominal Capacity

40 kWp

Average Specific Yield

1012 kWh/kWp

Total Estimated Loss

27.4%

Possible Gain

10% to 20%

CAPEX, OPEX

2.6 ₹/Wp, 0.3 ₹/Wp/a

Expenditure / Energy

N/A

Abstract

The plant is affected by moderate soiling. Due to the difficult access, the O&M activities such as visual inspection and module cleaning, might be disregarded. Several modules were laying on the ground likely due to a combination of a challenging installation and wind loads. It is recommended to (i) replace missing modules and reconnect strings, (ii) improve cleaning cycles, (iii) conduct proper inverter maintenance, (iv) implement anti-PID solutions and (v) re-string with individual MPPT assignments according to mechanical damages (IR inspection). The estimated production boost expected by the retrofitting actions lies between 10-20%.

Main Findings

The access to the roof is difficult. This could have caused module damages during handling and installation, which would likely lead to underperformance.

The open wasteland in the proximity of the system could be responsible for increased soiling issues.

Several modules were laying on the ground (disconnected) likely due to a combination of a challenging installation on the edge and strong wind loads.

The inverter fan filters (outlets) are partially blocked, leading to a higher risk of inverter shut down.

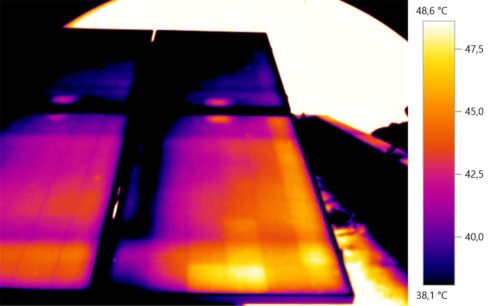

PID presence was discovered via on-site IV curve and thermographic inspection.

Module defects, such as Backsheet label detachment, broken glass and corrosion in the busbars, were also discovered. Strings with broken glass could underperform 30% due to irradiation reduction.

Impact on Performance

Heavy Soiling

Soiling losses of 4.7%, on average, were calculated from IV curve measurements of modules before and after cleaning.

Estimated Loss

≈ 4.7%

Potential Induced Degradation

There is evidence of PID effect, which could result in a performance loss of as high as 15% at the system level, based on PI Berlin on-site measurements (and considering expected power and the soiling factor).

Estimated Loss

≈ 14%

Near Shading

There is evidence of PID effect, which could result in a performance loss of as high as 15% at the system level, based on PI Berlin on-site measurements (and considering expected power and the soiling factor).

Estimated Loss

≈ 1.2%

Disconnected circuits

The disconnected modules result in a loss of 7.5%

Estimated Loss

≈ 7.5%

Total Estimated Energy Loss

≈ 27.4%

Proposed Solutions

The cleaning cycles shall be increased based on the results of a soiling study that adjusts the cleaning needs to each season (considering the surroundings).

Anti-PID measures shall be implemented in order to stop and reverse the degradation. PV modules (without PID), showing power drops above the warranty conditions shall be replaced. If the replacement is not possible, the modules shall be regrouped in power classes within the same string and assigned to individual MPPT.

Damaged modules by wind loads and broken glass shall be replaced and properly installed.

Module product defects (corrosion in busbars, defective labels) shall be monitored, whether the degradation continues or it has stabilized.