Site IV.10

Site ID

IV.10

Health

COD

2013

Nominal Capacity

100 kWp

Average Specific Yield

1074 kWh/kWp

Total Estimated Loss

20.5%

Possible Gain

5% to 15%

CAPEX, OPEX

0.8 ₹/Wp, 0.2 ₹/Wp/a

Expenditure / Energy

N/A

Abstract

The plant is strongly affected by snail trials. The origin is likely a combination of mechanical loads, from handling and installation (microcracks) and poor backsheet quality. However, the impact on the performance cannot be completely addressed without proper thermographic inspection and on-site power measurements. It is recommended to (i) analyze the evolution of snail trails and hotspots via yearly thermographic inspection of the modules, (ii) improve cleaning cycles based on soiling study and (iii) replace modules exceeding the manufacturer’s guaranteed performance drop and product warranties. The estimated production boost expected by the retrofitting actions lies between 5-15%.

Main Findings

Although installed next to a large field, moderate soiling was detected.

The inverter was found in a stand-by mode, i.e., disconnected from the grid.

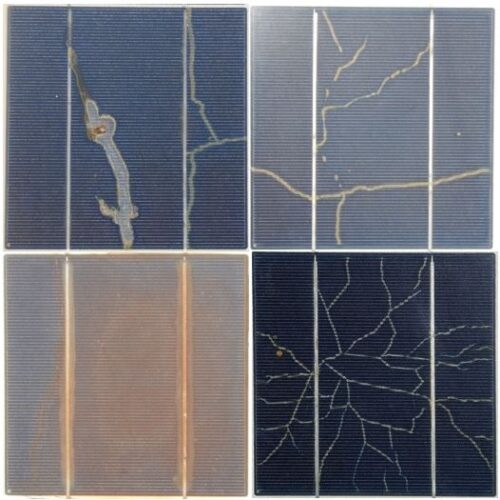

The majority of the modules presented a snail trail pattern, from moderate to severe stages.

Due to the difficult access to the roof, it is likely that the modules suffered mechanical stress during transport, handling and installation. The resulting microcracks are one of the sources of the snail trail effect in the modules.

String cables were occasionally spotted in contact with sharp edges, showing initial signs of damage.

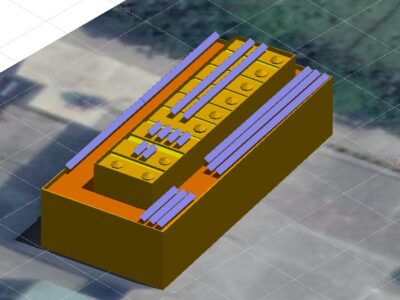

The plant was installed in a single module landscape orientation, with a very limited interrow spacing.

The module sample tested on-site showed a significant drop in the expected performance.

The lack of calibration of the irradiation sensor will not directly affect the performance of the system. However, the accurate recording of the onsite irradiation will provide confidence to the plant`s KPIs.

Impact on Performance

Near Shading

Based on the simulation, shading losses are estimated to be 5% at the system level.

Estimated Loss

≈ 5%

Potential Induced Degradation

Due to the inverter status during the IR inspection (disconnection, open-circuit), the thermographic analysis could not take place to evaluate PID. Based on on- site IV curve measurements, the PID effect could be responsible for 10-15% energy losses.

Estimated Loss

10%-15%

≈ 12.5%

Heavy Soiling

An average soiling factor of 3% was determined from IV curve measurements of sample modules, before and after cleaning.

Estimated Loss

≈ 3%

Total Estimated Energy Loss

≈ 20.5%

Proposed Solutions

The snail trails shall be monitored and assessed (via IR) whether the degradation has reached stabilization.

Modules with snail trails within similar degradation shall be re-grouped in the same strings, or at least assigned to one MPPT. The grouping shall be conducted based on infrared inspection with high irradiation levels and after cleaning activities.

PV modules showing power drops caused by product defects above the warranty conditions shall be replaced (7 yrs in operation < 10yrs - 90% power performance).

Cleaning cycles shall be increased and defined based on a soiling study that adjusts the cleaning needs to each season. Cleaning once a month during the dry season is not enough.

Damaged cables shall be replaced and those in contact with sharp edges shall be protected.

The inverter configuration (i.e., “waiting for sun”) shall be validated to eliminate the possibility of an internal failure. This issue shall be only related to “DC voltage not sufficient to allow for connection to the main network”.