Site II.8

Site ID

II.8

Health

COD

2017

Nominal Capacity

58.28 kWp

Average Specific Yield

783 kWh/kWp

Total Estimated Loss

17%

Possible Gain

13% to 17%

CAPEX, OPEX

4.8 ₹/Wp, 0.4 ₹/Wp/a

Expenditure / Energy

N/A

Abstract

The PV plant shows significant soiling caused by generator exhaust, smog and bird drops. A lack of structural integrity of the sheet metal roofing was detected, the foundations show signs of rust. Cracks of different severities were detected via EL inspection. It is recommended to: (i) conduct a reengineering of the strings according to the shading situation, (ii) increase the cleaning frequency to at least three times per month, (iii) reinforce the rusted metal sheets of the carport and (iv) relocate modules in strings based on the module damages. The estimated production boost expected by the retrofitting actions lies between 13% and 17%.

Main Findings

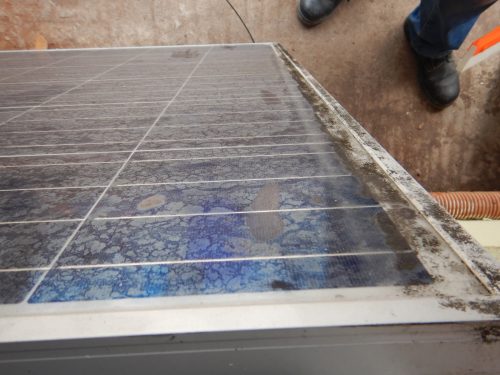

The modules are heavily soiled. There is no manual cleaning scheduled. The soiling is caused by a combination of smog and particles from the exhaust of the generators nearby.

There is no weather station, and hence no PR monitoring.

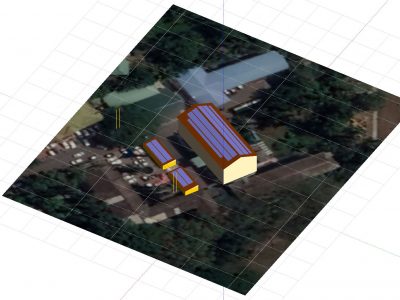

The carport in the parking area, on which part of the PV system is installed, is not stable and the structure is rusty.

Cables have been damaged by UV radiation. The pipes conveying the cables are brittle and are partly broken.

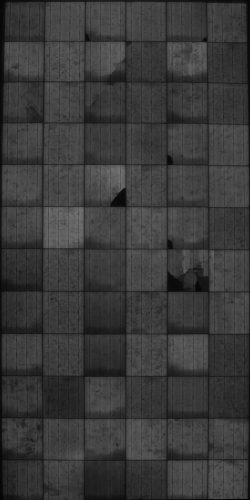

Cracks of different severities were detected via EL inspection.

Impact on Performance

Heavy Soiling

Soiling losses were determined to be 10% on average, based on the on-site measurements.

Estimated Loss

≈ 10%

Cell Cracks

Cell cracks are estimated to result in 7% performance loss at the system level

Estimated Loss

≈ 7%

Total Estimated Energy Loss

≈ 17%

Proposed Solutions

A weather station, or at least an irradiation sensor on the module plane, shall be installed so that the performance of the system can be properly determined.

Manual cleaning shall be implemented and scheduled based on the results of a soiling study that adjusts the cleaning needs to each season.

The mounting structure of the carport system shall be reinforced in order to ensure the structural integrity.

Modules with heavy cracks shall be grouped in the same string or at least assigned to one MPPT. The grouping will be conducted based on infrared inspection with high irradiation levels and after cleaning. A restringing of the modules from the shaded areas shall be conducted in the following way: modules with similar shading conditions shall be installed in the same string or at least assigned to one MPPT.