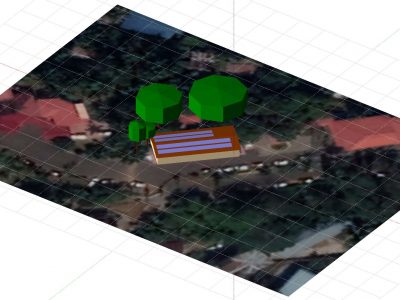

Site II.6

Site ID

II.6

Health

COD

2017

Nominal Capacity

27.9 kWp

Average Specific Yield

417 kWh/kWp

Total Estimated Loss

26%

Possible Gain

16% to 22%

CAPEX, OPEX

1.6 ₹/Wp, 0.9 ₹/Wp/a

Expenditure / Energy

N/A

Abstract

The PV plant is soiled by generator exhaust, bird droppings and foliage. Partial electrical inactivity at the cell level caused by mechanical damages was detected (likely induced during installation and O&M). It is recommended to (i) increase the cleaning cycles, (ii) modify the exhaust direction, (iii) trim the surrounding trees if allowed by the authorities, (iv) resort the modules according to level of mechanical damage and (v) install a weather station or at least an irradiation sensor on the module plane to quantify and monitor the Performance Ratio. The estimated production boost expected by the retrofitting actions lies between 16% and 22%.

Main Findings

Nearby trees cause significant shading on the system. There is no weather station.

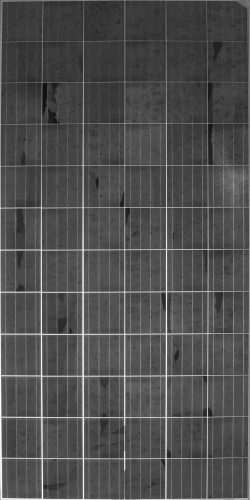

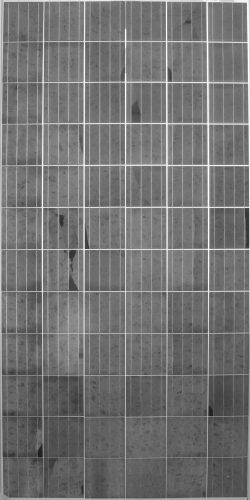

Moving between module rows is usually done by crossing over the modules, which often results in modules being stepped on. Since the modules are stepped on, cell damages are inevitable (cracks and broken cells). They could also occur during installation since the access to the roof is difficult.

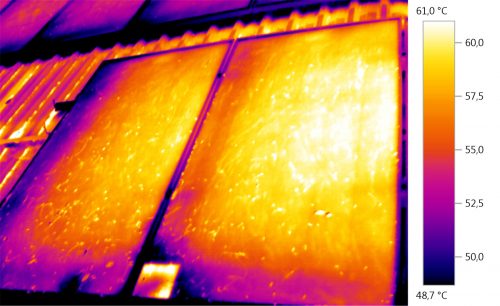

Soiling on the module surface is evident. The system is cleaned only by rain. Due to the flat tilt angle of the modules, the soil accumulates at the bottom edge of the modules causing shading effects.

Impact on Performance

Near Shading

The simulation shows significant shading losses caused by trees, which are close to 15%.

Estimated Loss

≈ 15%

Cell Cracks

Based on the amount of cracks and broken cells and corresponding inactive areas, the power loss is estimated to be 5% at the system level.

Estimated Loss

≈ 5%

Heavy Soiling

Soiling losses were determined to be 6% on average, based on the measurements on site.

Estimated Loss

≈ 6%

Total Estimated Energy Loss

≈ 26%

Proposed Solutions

A weather station, or at least an irradiation sensor on the module plane, shall be installed so that the performance of the system can be properly determined.

The trees surrounding the system shall be trimmed if allowed. Otherwise, a regrouping of the modules shall be conducted in the following way: modules with similar shading conditions shall be installed in the same string or at least assigned to one MPPT.

Manual cleaning shall be implemented and scheduled based on the results of a soiling study that adjusts the cleaning needs to each season.

Modules with heavy cracks shall be grouped in the same string or at least assigned to one MPPT. The grouping will be conducted based on infrared inspection with high irradiation levels and after cleaning.