Site I.8

Site ID

I.8

Health

COD

2018

Nominal Capacity

150 kWp

Average Specific Yield

775 kWh/kWp

Total Estimated Loss

12.5%

Possible Gain

0% to 0%

CAPEX, OPEX

1.2 ₹/Wp, 1.3 ₹/Wp/a

Expenditure / Energy

N/A

Abstract

The PV plant shows many cracks at the cell level caused by bad handling, high levels of soiling caused by debris and a strong deviation towards SE that reduces significantly the amount of the solar resource. It is recommended to (i) increase the cleaning frequency to at least three times per month, (ii) increase the albedo using white gravel and (iii) replace modules with product defects and (iv) conduct a resort the modules and strings with individual MPPT assignments according to the level of mechanical damage. The estimated production boost caused by the retrofitting actions lies between 11% and 14%.

Main Findings

The electroluminescense inspection revealed branched cracks in the modules caused by improper handling during installation and maintenance.

Heavy soiling caused mainly by debris was detected.

PV modules of different technologies were mixed in the same string.

The irradiation sensor was installed at the wrong tilt and was significantly soiled at the time of the visit.

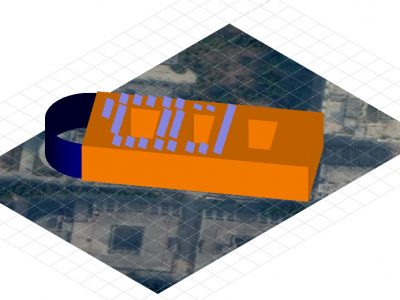

The PV plant has a strong deviation from South.

Scratches on the module backsheet were detected posing safety risks and increasing the risk of inverter disconnection due to loss of insulation.

Impact on Performance

Cell Cracks

The amount and type of cracks is likely to induce a performance loss of around 3%.

Estimated Loss

≈ 3%

Deviation from South

The deviation of the modules towards South-East leads to an estimated performance loss of around 2.5%.

Estimated Loss

≈ 2.5%

Total Estimated Energy Loss

≈ 12.5%

Proposed Solutions

Modules with heavy cracks shall be grouped in the same string or at least assigned to one MPPT. The grouping will be conducted based on infrared inspection with high irradiation levels and after cleaning. These modules with cracks will be grouped in strings with same MPPT.

Strings mixing two different technologies shall be rearranged in order to ensure that they are composed only by one technology type.

The cleaning cycles shall be increased and defined based on a soiling study that adjusts the cleaning needs to each season. Cleaning once a month during the dry season is not enough.

The irradiation sensor shall be cleaned and installed at the correct tilt.

Increasing the albedo from 0.2 to 0.5 by covering the ground with white gravel leads to an increase of the irradiation on tilted surface of at least 1.5%.