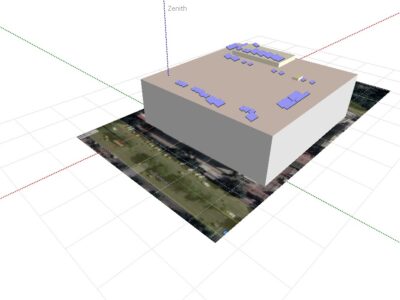

Site 2.8

Site ID

2.8

Health

COD

2018

Nominal Capacity

130 kWp

Average Specific Yield

925 kWh/kWp

Total Estimated Loss

29.48%

Possible Gain

11% to 17%

CAPEX, OPEX

0.3 ₹/Wp, 0.13 ₹/Wp/a

Expenditure / Energy

1.5 ₹/kWh to 0.9 ₹/kWh

Abstract

The PV plant has several broken or damaged modules. O&M staff was spotted to walk on the modules. Some of the modules are extremely dirty. Objects laying under the modules have been found and some back sheets are extremely dirty. Some parts of the sites are affected by heavy near shading. It is recommended to (i) improve O&M activities and cleaning cycles, (ii) restringing of the shaded modules, (iii) install an irradiation sensor, and (iv) clean up the objects laying under the modules. The estimated production boost expected by the retrofitting actions lies between 11% and 17%.

Main Findings

Poor Cable Management, cables not tied up among the substructure which makes operation and maintenance activities more difficult.

Back sheet-Modules heavy soiled due to poor cleaning and maintenance.

Objects under PV-Array reduce the ventilation and this may increase the temperature of the modules.

Minimum bending radius not considered; this may damage solar cables sooner than its normal lifetime.

Hot cells have been detected during the IR analysis.

Impact on Performance

Cell Cracks

Isolated parts and finger interruptions were found by Electroluminescence analysis.

Estimated Loss

≈ 6%

Underperformance

The underperformance of the measured

modules is around 13%

Estimated Loss

≈ 13%

Total Estimated Energy Loss

≈ 29.48%

Proposed Solutions

Objects under the PV-Array should be removed to allow proper ventilation and avoid further risks.

Solar cables should have a minimum bending radius to avoid early damages.

The modules with major EL failures can be compared with the manufacturing catalogue and if applicable they can be replaced.

The cleaning cycles shall be increased based on the results of a soiling study that adjusts the cleaning needs to each season.

Cables should be tied up, have a suitable labelling, and should be protected from UV.

The measured soiling loses is 2.1%. The cleaning cycle should be improved.

A weather station, or at least an irradiation sensor on the module plane, shall be installed so that the performance of the system can be properly determined.

Broken modules and cables should be replaced.

The maintenance staff should be trained to handle the modules in a careful manner.