Site 2.60

Site ID

2.60

Health

COD

2017

Nominal Capacity

10 kWp

Average Specific Yield

1131 kWh/kWp

Total Estimated Loss

42.8%

Possible Gain

14% to 16%

CAPEX, OPEX

3.88 ₹/Wp, 0.30 ₹/Wp/a

Expenditure / Energy

3.1 ₹/kWh to 2.7 ₹/kWh

Abstract

The plant is heavily affected by soiling. Some modules are shaded causing hotspots. Structural earthing is incomplete and corroded. The PV cables loosely hanging, poorly inter- connected, and with low bending radius were found. It is recommended to (i) optimize cable layout, (ii) remove shading objects, (iii) retrofit the mounting structure, and (iv) install an irradiation sensor on the tilted plane to compute and check the Performance Ratio. The estimated production boost expected by the retrofitting actions lies between 14% and 16%.

Main Findings

Poor cable management: The minimum cable bending radius is not considered, no string labelling was found; and a non- standard way of connection string cable to module.

Non-standard cable selection for string wire.

Non-conventional iron wire (corroded) used for earthing

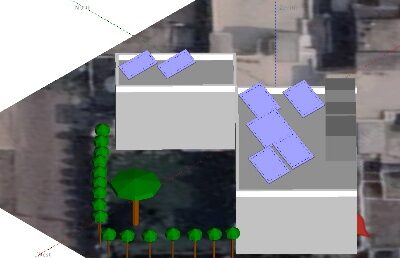

Modules within the same string have a different orientation.

Modules’ structure disregards the height of the parapet and nearby objects resulting in shading of the modules.

Bus bar corrosion/burn marks observed on some modules.

No weather station was found on site.

Filters of the inverters were found soiled.

Impact on Performance

Near Shading

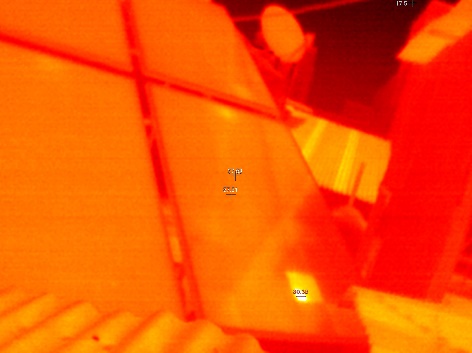

IR analysis showed evidence of hot spots caused by near shading objects. The near shading losses account for up to 4.8%.

Estimated Loss

≈ 4.8%

Self Shading

According to the simulation of the system, the self-shading losses account for up to 7.8%.

Estimated Loss

≈ 7.8%

Heavy Soiling

The on-site measured soiling losses were estimated in 15.3% from IV curve measurements.

Estimated Loss

≈ 15.3%

Cell Cracks

According to the number of cracks discovered via EL imaging; the system is not expected to have large power losses due to inactive areas.

Estimated Loss

≈ 2%

Underperformance

The underperformance of the measured modules is around 12.9%.

Estimated Loss

≈ 12.9%

Total Estimated Energy Loss

≈ 42.8%

Proposed Solutions

The cleaning cycles shall be increased based on the results of a soiling study that adjusts the cleaning needs to each season.

If possible, shading objects should be removed. Additionally, restringing of the modules in the shaded areas shall be conducted in the following way: modules with similar shading conditions shall be installed in the same string or MPPT.

Include in the O&M practices the cleaning of the ventilation system of the inverters.

A weather station, or at least an irradiation sensor on the module plane, shall be installed so to determine the performance of the system.

The rusted elements of the grounding shall be substituted, and all the connections have to be done to the grounding hole of the module frame.

Cables should be tied up among the substructure, have a minimum bending radius to avoid early damages, and have a suitable labelling.

The tables with different orientation shall be aligned with the rest of the tables towards true south.