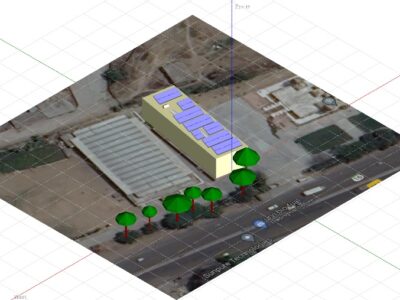

Site 2.59

Site ID

2.59

Health

COD

2018

Nominal Capacity

40 kWp

Average Specific Yield

1440 kWh/kWp

Total Estimated Loss

31.01%

Possible Gain

1% to 4%

CAPEX, OPEX

3.7 ₹/Wp, 0.32₹/Wp/a

Expenditure / Energy

28.9 ₹/kWh to 9.4 ₹/kWh

Abstract

Some modules with backsheet scratches were detected. Cables loosely hanging from the modules were found. Module-to-module earthing is absent. It is recommended to (i) add earthing connections between modules, (ii) optimize the cable layout, (iii) replace modules with back-sheet damage, (iv) replace rusted components of the mounting structure, and (v) install a weather station or at least an irradiation sensor on the module plane to quantify and monitor the performance ratio. The estimated production boost expected by the retrofitting actions lies between 1.2% and 3.7%.

Main Findings

Poor cable management: Cables loosely hanging from the structure, and exposed to ambient. The minimum cable bending radius is not respected. Connectors are soiled.

Cable conduits degraded.

Improper access to the site.

The joints and bolts in the mounting structures are rusted.

Modules shaded by tree and the LA on site, causing module hotspots.

Module-to-module equipotential bonding is absent.

No weather station identified on site.

IR analysis shows presence of hotspots, from shading and cementing. This may indicate irreversible cell damage.

Impact on Performance

Heavy Soiling

Based on the IV curve measurements, the soiling loss is estimated to be 7.4%. Modules are affected by cementing.

Estimated Loss

≈ 7.4%

Cell Cracks

The EL image reveals presence of branched cracks, isolated parts, and back-sheet scratches, which are expected to impact performance and safety.

Estimated Loss

≈ 5%

Underperformance

Based on the IV curve measurements, the estimated underperformance is 15.7% for the measured modules.

Estimated Loss

≈ 15.7%

Near Shading

According to the PVsyst simulations, the near shading losses account to 0.91%.

Estimated Loss

≈ 2%

Total Estimated Energy Loss

≈ 31.01%

Proposed Solutions

Strings, tables, and inverters shall have suitable labelling (UV-resistant if applicable).

A proper cable rack layout shall be used to prevent cable degradation from ambient conditions.

Degraded cable conduits shall be replaced with suitable ones.

The cleaning cycles shall be increased based on the results of a soiling study.

Modules with back-sheet scratches shall be replaced to avoid safety threats.

A re-sorting shall be conducted to have lower performing modules in the same string or at least assigned to individual MPPT.

A weather station, or at least an irradiation sensor on the module plane shall be installed.

Earthing connections between modules shall be added.

Rusted joints and bolts in the structure shall be replaced. To prevent such problems, metal objects vulnerable to corrosion can be painted with zinc.

If possible, LA that causes shading shall be moved from module vicinity and the tree causing shading shall be trimmed.