Site 2.41

Site ID

2.41

Health

COD

2017

Nominal Capacity

29.76 kWp

Average Specific Yield

740 kWh/kWp

Total Estimated Loss

11.6%

Possible Gain

8% to 47%

CAPEX, OPEX

2.18 ₹/Wp, 0.22 ₹/Wp/a

Expenditure / Energy

5.5 ₹/kWh to 0.9 ₹/kWh

Abstract

Cable management on site observed in poor condition. Modules clamps and bolts damaged. It is recommended to (i) optimize the cable layout, (ii) replace broken system components, (iii) relocate installations on roof edge, (iv) relocate shading objects, (v) retrofit the mounting structure, (vi) add module to module equipotential bonding, and (vii) install a weather station or at least an irradiation sensor on the module plane. The estimated production boost expected by the retrofitting actions lies between 8% and 46.9%.

Main Findings

Poor cable management: Cables in poor condition. Cables exposed to ambient. Missing string labelling. Cables and connectors degraded and broken from poor crimping.

Cable conduits broken and molten.

Disconnected string due to broken cable.

Cement remains stuck on modules, and cell delamination found.

Improper roof access and no walkway found on site.

Modules installed beyond roof edge in high wind zones.

Multiple module orientations found on site.

Poor module racking due to damaged and faulty clamps and bolts, and improper rail placement.

Module to module equipotential bonding missing.

Modules shaded by water pipes, water heater and water tanks in the installation area.

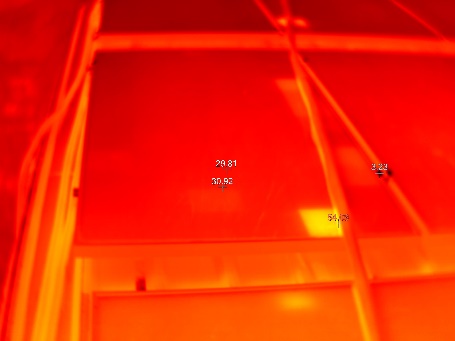

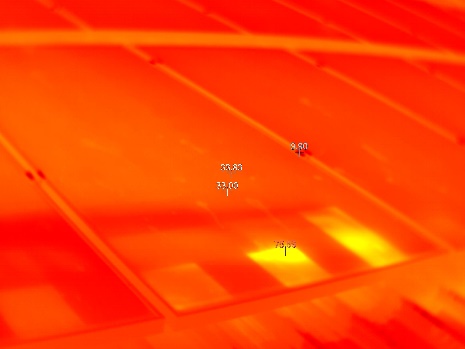

IR analysis reveals presence of hot cells from water pipes running over modules.

Modules shaded by the water tanks cause hotspots and hot cells from shading. This may indicate irreversible cell damage.

Impact on Performance

Heavy Soiling

Based on the IV curve measurements, the soiling loss is estimated to be 4.8%. Modules are also soiled from cementing.

Estimated Loss

≈ 4.8%

Underperformance

Based on the IV curve measurements, the estimated underperformance is 0.6% for the measured modules.

Estimated Loss

≈ 0.6%

Near Shading

According to PVsyst simulation, the near shading losses account to 1.85%.

Estimated Loss

≈ 1.85%

Total Estimated Energy Loss

≈ 11.6%

Proposed Solutions

Strings, tables, and inverters should have a suitable labelling (UV-resistant).

Broken cables, connectors and conduits shall be immediately replaced to restore production from disconnected string and safety.

The cleaning cycles shall be increased based on the results of a soiling study.

Modules with stuck cement remains shall be replaced since they generate permanent hotspots.

Module to module earthing connections shall be added.

If possible, a better roof access and walkway shall be provided for safer and easier O&M activity.

Installations shall be moved away from the roof edge to prevent damage from higher wind loads.

If the site layout allows, variation in orientations shall be reduced to reduce mismatch losses.

A weather station, or at least an irradiation sensor on the module plane shall be installed.

Damaged clamps and bolts shall be replaced. The rails shall be properly placed for an even load distribution at the clamping points.

Water pipes, water heater and tanks causing shading shall be relocated to reduce shading impact and hotspot damage.