Site 2.37

Site ID

2.37

Health

COD

2018

Nominal Capacity

10 kWp

Average Specific Yield

1172 kWh/kWp

Total Estimated Loss

19.4%

Possible Gain

5% to 7%

CAPEX, OPEX

1.54 ₹/Wp, 0 ₹/Wp/a

Expenditure / Energy

1.2 ₹/kWh to 0.9 ₹/kWh

Abstract

Cables with low bending radius were found. Several issues concerning mounting structure and components were observed. It is recommended to (i) optimize the cable layout, (ii) relocate the modules from roof boundary, (iii) re-string shaded modules, (iv) retrofit the mounting structure, (v) trim the surrounding trees, and (vi) install a weather station or at least an irradiation sensor on the module plane. The estimated production boost expected by the retrofitting actions lies between 5.1% and 7.3%.

Main Findings

Poor cable management: Cables with low bending radius. String labelling missing.

Paint remains stuck on module.

Module installed at roof boundary with no protection against wind loads.

Vertical post fixed at different angle and depth on each ballast block.

Support strap connecting rafter and post fixed at varying angle and depth on each ballast block.

Improper fixation of purlin on rafter.

Screws and nuts used in the structure are rusted.

L channel rafter used on one table deformed due to improper handling.

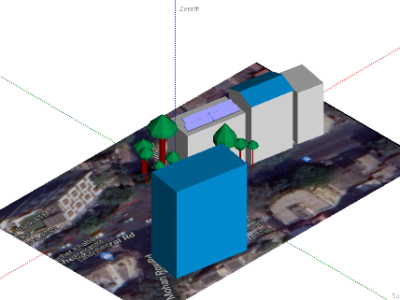

The PV plant is partly surrounded by buildings, trees and a shed roof that cast shadows on the modules.

No weather station found on site.

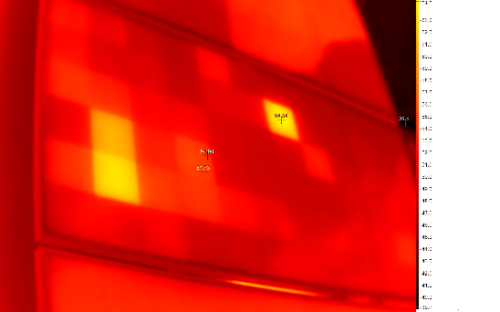

IR analysis reveals presence of hot cells.

Impact on Performance

Heavy Soiling

Based on the IV curve measurements, the soiling loss is estimated to be 2.2%.

Estimated Loss

≈ 2.2%

Cell Cracks

The EL image reveals presence of few cracks and soldering defects. These defects are not expected to impact performance at their given state.

Estimated Loss

≈ 2%

Underperformance

Based on the IV curve measurements, the estimated underperformance is 5.1% for the measured modules.

Estimated Loss

≈ 5.1%

Near Shading

According to PVsyst simulation, the near shading losses account to 5.2%.

Estimated Loss

≈ 5.23%

Total Estimated Energy Loss

≈ 19.4%

Proposed Solutions

Strings, tables, and inverters should have a suitable labelling (UV-resistant).

Modules with foreign material stuck on glass shall be replaced since they can generate permanent hot cells that may pose performance and safety threat in the long run.

Modules installed at the module boundary shall be moved away from it to prevent damage from wind loads.

Retrofitting actions shall be done on the structure to have the vertical posts, support straps, and structure purlins properly fixed on the structure. This reduces the module misalignment observed on site.

Deformed L channel rafters shall be replaced since their functionality may be reduced or compromised.

Rusted components of the structure shall be replaced if possible. To prevent such problems, metal objects vulnerable to corrosion can be painted with zinc.

The trees surrounding the system shall be trimmed if allowed.

A re-stringing of modules shall be conducted to have shaded modules in the same MPPT.

A weather station, or at least an irradiation sensor on the module plane shall be installed