Site 2.31

Site ID

2.31

Health

COD

2016

Nominal Capacity

10.16 kWp

Average Specific Yield

1039 kWh/kWp

Total Estimated Loss

12.46%

Possible Gain

2% to 3%

CAPEX, OPEX

4.22 ₹/Wp, 0 ₹/Wp/a

Expenditure / Energy

8.6 ₹/kWh to 5.7 ₹/kWh

Abstract

Loosely hanging cables with low bending radius were found. Several modules show delamination, corrosion of busbars, and degrading sealant around the junction box. It is recommended to (i) optimize the cable layout, (ii) re-sort the modules with different power rating and year of manufacture, (iii) retrofit the mounting structure, (iv) monitor manufacturing issues for further degradation and a possible warranty claim, and (v) install a weather station or at least an irradiation sensor on the module plane. The estimated production boost expected by the retrofitting actions lies between 3% and 25%.

Main Findings

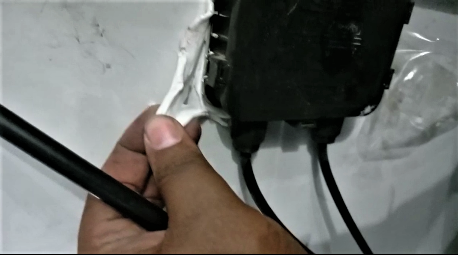

Poor cable management: Loosely hanging cables with low bending radius. In addition, the cables and connectors are exposed to ambient.

The labelling used in cables to the inverter are in poor condition.

Several modules show signs of delamination.

Modules with different power rating and year of manufacture in the same string.

Corroded busbars were observed in many modules.

Modules directly bolted onto the table structure which does not provide proper support to top part of the module. Some diagonal straps used in structure damaged. Structure components rusted at joints.

The sealant used around junction box is degrading.

No weather station identified on site.

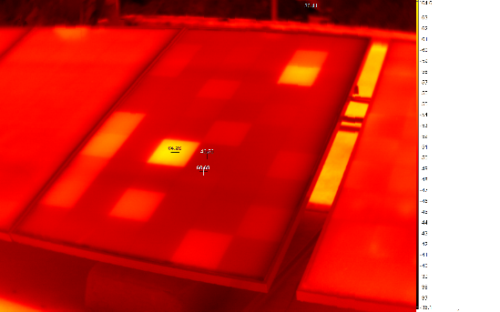

IR analysis shows presence of hot cells.

Impact on Performance

Heavy Soiling

Based on the IV curve measurements, the soiling loss is estimated to be 1.4%.

Estimated Loss

≈ 1.4%

Cell Cracks

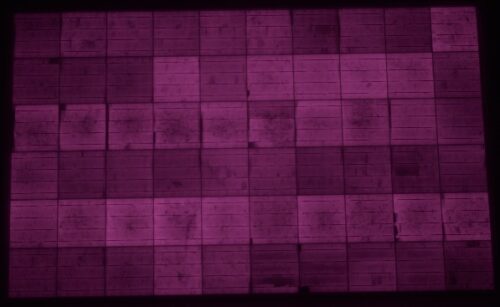

The EL image reveals presence of branched cracks, which arises due to issues in transportation or handling.

Estimated Loss

≈ 4%

Underperformance

Based on the IV curve measurements, the estimated underperformance is 5% for the measured modules.

Estimated Loss

≈ 5%

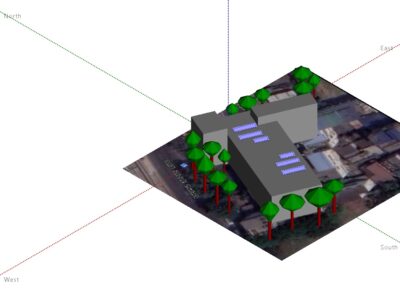

Near Shading

According to PVsyst simulation, the near shading losses account to 1.48%.

Estimated Loss

≈ 1.48%

Total Estimated Energy Loss

≈ 12.46%

Proposed Solutions

Strings, tables, and inverters should have a suitable labelling (UV-resistant).

The cable layout can be optimized; the minimum cable bending radius is 10x the cable diameter.

Modules with degrading sealant around the junction box pose a safety risk and shall be replaced.

A re-sorting of modules shall be conducted to have modules with same year of manufacture in the same string or at least same MPPT.

A weather station, or at least an irradiation sensor on the module plane shall be installed.

Defects corresponding to manufacturing issues like delamination and corrosion of busbars shall be monitored for further degradation for a possibly warranty claim in the future.