Site 2.29

Site ID

2.29

Health

COD

2016

Nominal Capacity

5 kWp

Average Specific Yield

870 kWh/kWp

Total Estimated Loss

41.6%

Possible Gain

18% to 20%

CAPEX, OPEX

5.48 ₹/Wp, 0.43 ₹/Wp/a

Expenditure / Energy

4.6 ₹/kWh to 4.1 ₹/kWh

Abstract

Cables layout with loosely hanging cables and low bending radius were found. Joints and structures are rusted. Modules were observed to be heavily soiled. It is recommended to (i) optimize cable layout to have optimal bending radius, (ii) increase the cleaning frequency to reduce performance loss and further module damage, (iii) provide safety railings for easier access for the O&M team, and (iv) install a weather station or at least an irradiation sensor on the module plane to monitor the performance ratio. The estimated production n boost expected by the retrofitting actions lies between 18% and 20%.

Main Findings

Poor cable management: Loosely hanging cables from the structure due to broken tags. The minimum cable bending radius is not respected.

The joints and bolts used for structural connections are significantly rusted.

Access to the tables is unsafe and uneasy.

Module frames shows signs of corrosion and rusting.

Inverter room was without proper ventilation.

Modules are heavily soiled, due to which the module output is shaded from soiling.

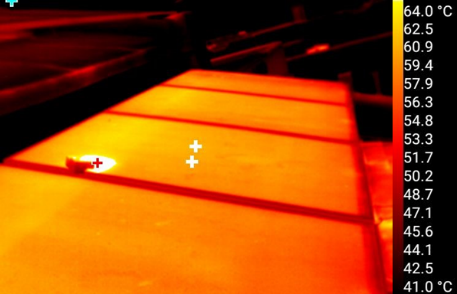

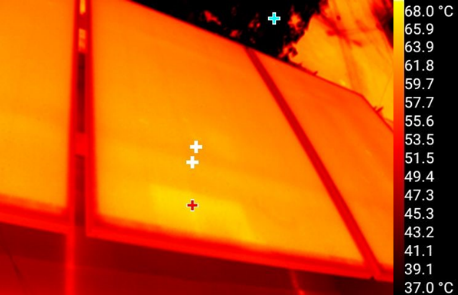

The modules are shaded by stray objects, causing hotspots that may cause irreversible cell damage.

Impact on Performance

Heavy Soiling

The system performance was affected by soiling loss of 21%, estimated from IV curve measurements. IR analysis shows presence of hotspots from soiling. Such hotspots may indicate irreversible cell damage due to shading from soiling.

Estimated Loss

≈ 21%

Underperformance

Based on the IV curve measurements, the estimated underperformance is 20% for the measured modules.

Estimated Loss

≈ 20%

Total Estimated Energy Loss

≈ 41.6%

Proposed Solutions

The cable layout shall be optimized; the minimum bending radius is 10x times the cable diameter. UV protection measurements shall be taken by using suitable rack with roof or cable coating.

The cleaning cycles shall be increased based on the results of a soiling study that adjusts the cleaning needs to each season.

Ideally, the modules permanently damaged from irreversible cell damage shall be replaced.

Safety railings shall be provided for safer access for cleaning and the O&M operations in general.

Rusted clamps, joints, and structure shall be replaced.

A weather station, or at least an irradiation sensor on the module plane shall be installed so that the performance of the system can be properly determined.