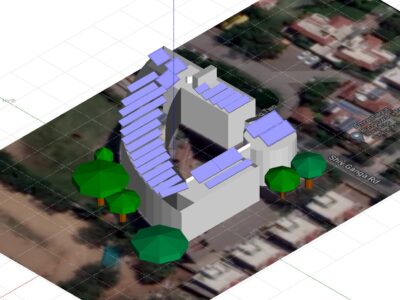

Site 2.16

Site ID

2.16

Health

COD

2018

Nominal Capacity

104 kWp

Average Specific Yield

1356 kWh/kWp

Total Estimated Loss

28.3%

Possible Gain

5% to 10%

CAPEX, OPEX

1.9 ₹/Wp, 0.12 ₹/Wp/a

Expenditure / Energy

2.8 ₹/kWh to 1.4 ₹/kWh

Abstract

The PV plant has several broken or missing modules due to high wind loads and poor mounting structure design. The cables don’t meet the minimum bending radius and lack labelling. Two tables are oriented differently as the rest. Fixation method of the modules is rusted and bonding between modules is absent. It is recommended to (i) improve mounting structure, (ii) change broken modules, (iii) restring shaded modules, (iv) remove objects under modules, and (v) include inverter in cleaning activities. The estimated production boost expected by the retrofitting actions lies between 5 and 10%.

Main Findings

Poor cable management: The minimum cable bending radius is not considered and no string labelling was found.

Modules are installed outside of roof edges in a high wind zone, resulting in damaged and missing modules.

Two broken modules were found on site.

Two tables have a different orientation

from the rest of the tables.

The table structure is fixed to the rooftops’ perimeter wall with wea foundations and welded profiles for structural bonding between tables.

Modules are fixed using rusted J-hooks and no clearance is found between modules.

The LA is bent and casting a shadow over the system during the morning.

PVC pipes stored under the modules can damage their back-sheet.

An inverter presents heavy degrees of soiling, and its fan is very noisy, which might lead to break down.

Impact on Performance

Heavy Soiling

The on-site measured soiling losses were estimated in 6.0% from IV curve measurements.

Estimated Loss

≈ 6%

Cell Cracks

According to the number of cracks discovered via EL imaging; the system is not expected to have large power losses due to inactive areas.

Estimated Loss

≈ 2%

Underperformance

The underperformance of the measured modules is around 17%.

Estimated Loss

≈ 17%

Near Shading

Several objects, such as, a water tank, walls, and the LA cast shadows over the system. According to the simulation of the system, the near shading losses account for up to 2.3%.

Estimated Loss

≈ 2.3%

Total Estimated Energy Loss

≈ 28.3%

Proposed Solutions

Broken and missing modules shall be replaced.

The tables with different orientation shall be aligned with the rest of the tables towards true south.

Solar cables should have a minimum bending radius to avoid early damages and string labelling should be included.

The foundation and fixing method of the mounting structure must be improved to withstand the wind loads.

A re-stringing of the modules from the shaded areas shall be conducted in the following way: modules with similar shading conditions shall be connected in the same string or at least assigned to individual MPPTs.

Include in the O&M practices the cleaning of the ventilation system of the inverters.

The modules that might be affected by PID shall be resorted based on an IR sorting of the entire site.

Objects under the PV-Array should be removed to prevent damage of the module’s back-sheet.

The module fixation method shall be improved including a bonding and clearance between the modules.