Site I.1

Site ID

I.1

Health

COD

2016

Nominal Capacity

180 kWp

Average Specific Yield

631 kWh/kWp

Total Estimated Loss

16%

Possible Gain

13% to 17%

CAPEX, OPEX

1.3 ₹/Wp, 1.2 ₹/Wp/a

Expenditure / Energy

N/A

Abstract

The PV plant shows high levels of soiling, as well as losses of production due to near shadings and an inconsistency of the inclination and orientation of the modules. The modules are very hotspot sensitive and show also significant mechanical damages. It is recommended to (i) conduct a reengineering of the modules and strings with individual MPPT assignments, (ii) increase the cleaning frequency to at least twice per month and (iii) use of gravel that increases the reflective properties of the ground. The estimated production boost expected by the retrofitting actions lies between 13% and 17%.

Main Findings

Heavy soiling even though the visit took place 3 days after a heavy rain and hail storm fell. However, in this period the soiling on the modules was already evident and likely to have an impact on the performance.

Shading is another common issue throughout the system. Small walls, antennas and other objects are the main source of near shading.

The PV tables have multiple azimuthal orientations. This leads to current mismatch on string and voltage mismatch on inverter level.

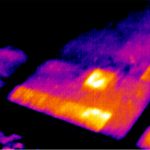

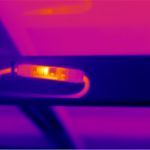

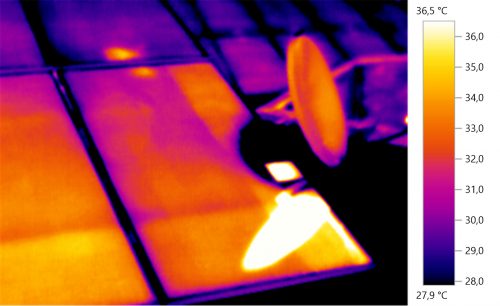

The installed modules are very hotspot sensitive, which could be detected during the infrared analysis.

The irradiation sensor is improperly installed providing inaccurate readings, and thus, leading to an inaccurate PR calculation.

Impact on Performance

Heavy Soiling

Soiling measurements were conducted measuring both the short circuit current and nominal power before and after cleaning at irradiations of > 700 W/m2. The estimated soiling factor is in the range of 5% - 12% depending on the location at site.

Estimated Loss

5%-12%

≈ 8.5%

Near Shading

The near shadings are responsible for an irradiation reduction on the tilted plane of approx. 3% at system level.

Estimated Loss

≈ 3%

Deviation from South

The inconsistency of the azimuthal orientation leads to a mismatch loss of approximately 1.5%.

Estimated Loss

≈ 1.5%

Cell Cracks

The amount and type of cracks, and cells in short circuit found in the selected modules during the electroluminescense inspection, reduce the nominal power of the PV plant by 2% - 4%. This statement bases on the extrapolation of the results of the sample measures.

Estimated Loss

2%-4%

≈ 3%

Total Estimated Energy Loss

≈ 16%

Proposed Solutions

A regrouping of the modules shall be conducted in the following way: modules with similar shading conditions shall be installed in the same string or at least assigned to one MPPT. Additionally, modules with heavy cracks shall be grouped in the same string or at least assigned to one MPPT. The grouping will be conducted based on infrared inspection with high irradiation levels and after cleaning.

A modification of the tilt angle to 24° will generate a performance boost of approx. 0.5%.

Additionally, it is advisable to create strings with less modules in series in order to reduce the near shading effect. A DC/DC converter at the inverter entrance will be needed to reach the minimal MPP voltage. This represents a performance boost of approx. 2%-3%.

The irradiation sensor should be reinstalled to provide accurate readings.

The cleaning cycles shall be increased based on the results of a soiling study that adjusts the cleaning needs to each season.

Covering the ground with white gravel increases the albedo factor to 0.5, leading to performance boost of 1.7%.