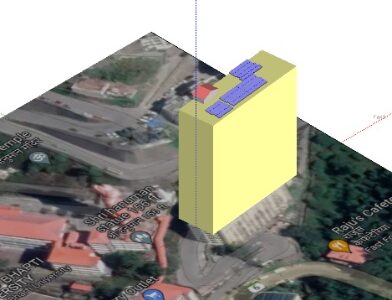

Site 2.43

Site ID

2.43

Health

COD

2018

Nominal Capacity

160 kWp

Average Specific Yield

759 kWh/kWp

Total Estimated Loss

22.52%

Possible Gain

14% to 40%

CAPEX, OPEX

1.2 ₹/Wp, 0.11 ₹/Wp/a

Expenditure / Energy

1.6 ₹/kWh to 0.6 ₹/kWh

Abstract

Cable management on site observed in poor condition. A module with glass breakage was connected to the system. It is recommended to (i) optimize the cable layout, (ii) replace modules with defects, (iii) increase cleaning cycles, (iv) relocate shading objects, (v) re-sort lower performing modules, (vi) re-string modules with same orientation, and (vii) install a weather station or at least an irradiation sensor on the module plane. The estimated production boost expected by the retrofitting actions lies between 13.6% and 39.6%.

Main Findings

Poor cable management: Degraded cables. Cables exposed to ambient. Missing labelling at string and module end.

Some cables are routed through the walkway, increasing the chances of causing cuts and abrasions.

Modules with broken glass connected to the system.

Foreign objects placed on PV tables.

Missing walkways on some sections of

the system.

Some modules installed over walkways.

Multiple module orientations connected to the same string.

Module structure and installation roof found to be rusted and in poor condition.

No weather station found on site.

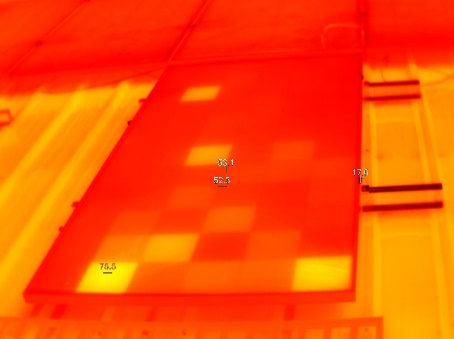

IR analysis reveals presence of hot cells due to module cementing.

Impact on Performance

Heavy Soiling

Based on the IV curve measurements, the soiling loss is estimated to be 5.1%. Modules are affected by cementing.

Estimated Loss

≈ 5.1%

Near Shading

Modules shaded by vegetation and nearby pipes. According to PVsyst simulation, the near shading losses account to 2.04%.

Estimated Loss

≈ 2.04%

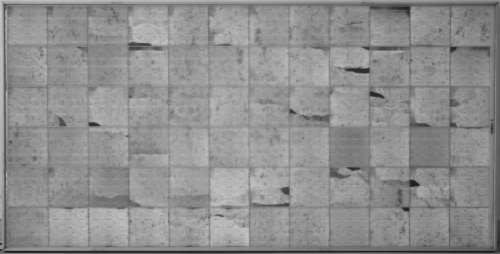

Cell Cracks

The EL image reveals presence of branched cracks and isolated parts indicating issues from transportation or handling. These defects generate hotspots, and pose both performance and safety threat.

Estimated Loss

5%-3%

≈ 4%

Underperformance

Based on the IV curve measurements, the estimated underperformance is 5.9% for the measured modules.

Estimated Loss

≈ 5.9%

Total Estimated Energy Loss

≈ 22.52%

Proposed Solutions

Strings, tables, and inverters should have a suitable labelling (UV-resistant).

A proper cable rack layout shall be used to prevent further cable degradation from ambient conditions.

The cleaning cycles shall be increased based on the results of a soiling study.

Module with broken glass shall be immediately replaced as it poses severe performance and safety threat.

Foreign objects found on modules shall be removed.

A properly anchored walkway shall be provided for safer and easier O&M activity.

A re-sorting shall be conducted to have lower performing modules in the same string, or at least the same MPPT.

A re-stringing shall be conducted to have modules from one orientation in the same string, or at least the same MPPT.

Rusted structure and roof parts shall be replaced if possible. To prevent such problems, metal objects vulnerable to corrosion can be painted with zinc.

A weather station, or at least an irradiation sensor on the module plane shall be installed.

Shading objects like pipe and vent shall be moved from module vicinity. If possible, vegetation causing shading shall be trimmed or removed.