Site IV.2

Site ID

IV.2

Health

COD

2014

Nominal Capacity

80 kWp

Average Specific Yield

874 kWh/kWp

Total Estimated Loss

18.1%

Possible Gain

17% to 25%

CAPEX, OPEX

1.9 ₹/Wp, 0.1 ₹/Wp/a

Expenditure / Energy

N/A

Abstract

The PV plant is affected by significant near shadings caused by surrounding trees in the South and East part of the system and advanced PID degradation. Furthermore, the modules showed substantial underperformance and affection by shunts. It is recommended to (i) replace missing fastening screws, (ii) conduct a string reengineering with individual MPPT assignments, based on IR inspection, (iii) replacement of modules exceeding the manufacturer’s guaranteed performance drop and (iv) replacement of modules with defective J-boxes. The estimated production boost caused by the retrofitting actions lies between 17-25%.

Main Findings

The system is not properly grounded.

The screws of the fastening clamps are not tightened correctly.

The angle of the irradiation sensor deviates slightly from the module angle.

The modules present different types of J- box failure types, e.g., overheated, open or missing lid.

String cables damaged by, or in contact with sharp edges were spotted.

Modules with broken front glass were found.

Cable ties broke, hence the module cables and connectors are loosely hanging.

Several modules with snail trails were found during the visual inspection.

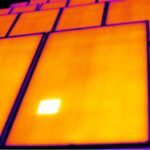

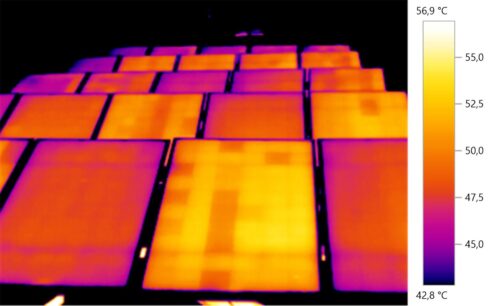

Several hot spots were discovered in the plant.

Impact on Performance

Heavy Soiling

Soiling losses were determined based on the measurements on-site to be 1.2%, on average.

Estimated Loss

≈ 1.2%

Near Shading

Near shading is caused by nearby trees.

Estimated Loss

≈ 6.9%

Potential Induced Degradation

PID leads to a performance loss of as high as 29% at the module level based on the measurements conducted on site. The degradation is in a fairly advanced stage. The impact at the system level is estimated to be around 10%.

Estimated Loss

≈ 10%

Total Estimated Energy Loss

≈ 18.1%

Proposed Solutions

The missing fastening screws should be replaced and all screws should be checked.

An anti-PID measure, such as anti-PID box, should be implemented in order to stop or reverse the degradation.

The trees surrounding the system should be trimmed if allowed. Otherwise, a restringing of the modules should be conducted in the following way: modules with similar shading conditions should be installed in the same string or at least assigned to one MPPT.

PV modules showing power drops above the warranty conditions should be replaced. If the replacement is not possible, the modules should be regrouped in power classes within the same string and assigned to individual MPPT.

Modules with any defect on the J-box should be immediate replaced (safety, operation and reliability issues).