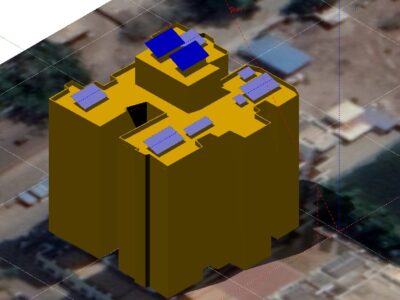

Site III.7

Site ID

III.7

Health

COD

2017

Nominal Capacity

70.4 kWp

Average Specific Yield

1251 kWh/kWp

Total Estimated Loss

33.2%

Possible Gain

15% to 30%

CAPEX, OPEX

2.9 ₹/Wp, 0.4 ₹/Wp/a

Expenditure / Energy

N/A

Abstract

The PV plant shows significant levels of soiling caused by city pollution, modules with an important amount of warm cells and a variety of crack types. Furthermore, the modules showed substantial underperformance and affection by product defects. It is recommended to (i) increase cleaning cycles, (ii) conduct a string reengineering with individual MPPT assignments, based on IR inspection, (iii) replacement of modules exceeding the manufacturer’s guaranteed performance drop and (iv) replacement of modules with defective J-boxes. The estimated production boost caused by the retrofitting actions lies between 15% and 30%.

Main Findings

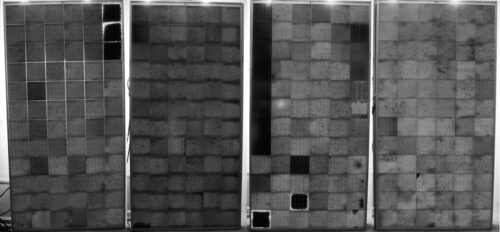

Electroluminescence analysis revealed a variety of module failure types, both from manufacturing defects, as well as from handling and installation practices.

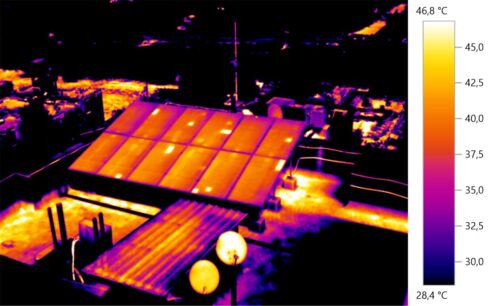

The last modules at the West and East sides of the tables are affected by shadings from the position of the wall and from antennas.

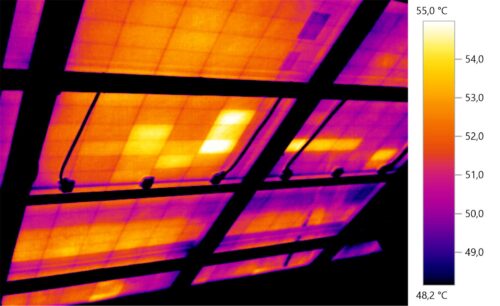

An important amount of warm cells were spotted via thermographic inspection.

The modules present different types of J- box failure types, e.g., overheated, open or missing lid.

String cables damaged by, or in contact with sharp edges were spotted.

From the module samples, the on-site IV curve measurements indicated that the power performance lies 25% and 19%, beneath the minimum expected value (according to label values and natural degradations), for full cell and HC cell, respectively.

The new modules installed early this year (Half-cut cells) showed a significantly lower performance via on-site IV curve measurements.

Although half-cut cell modules have been recently installed, the cells already have an abnormal thermal behavior.

The amount and type of cracks found during electroluminescence inspection is likely to induce a drop of the nominal power of around 8-10%.

Impact on Performance

Heavy Soiling

Soiling losses were determined based on the measurements on-site to be 4.2%, on average.

Estimated Loss

≈ 4.2%

Cell Cracks

The amount and type of cracks found during electroluminescence inspection is likely to induce a drop of the nominal power of around 8-10%.

Estimated Loss

8%-10%

≈ 9%

Total Estimated Energy Loss

≈ 33.2%

Proposed Solutions

A weather station, or at least an irradiation sensor shall be installed on- site to obtain reliable information, i.e., for the plant performance ratio calculation.

Modules with multiple cracks shall be re- grouped in the same string, or at least assigned to one MPPT. The grouping shall be conducted based on infrared inspection with high irradiation levels and after cleaning activities.

The cleaning cycles shall be increased and defined based on a soiling study that adjusts the cleaning needs to each season. Cleaning once a month during the dry season is not enough.

PV modules showing power drops above the warranty conditions shall be replaced. If the replacement is not possible, the modules shall be regrouped in power classes within the same string and assigned to individual MPPT.